Maneki Signage helps Singapore businesses become BCA-compliant on accessibility signs

Posted by DonovanThe information provided in this article is intended you help Singapore businesses better understand Braille signage and accessibility sign standards, and links directly to international (ADA) and local (BCA) documentation containing all the technical details on compliance.

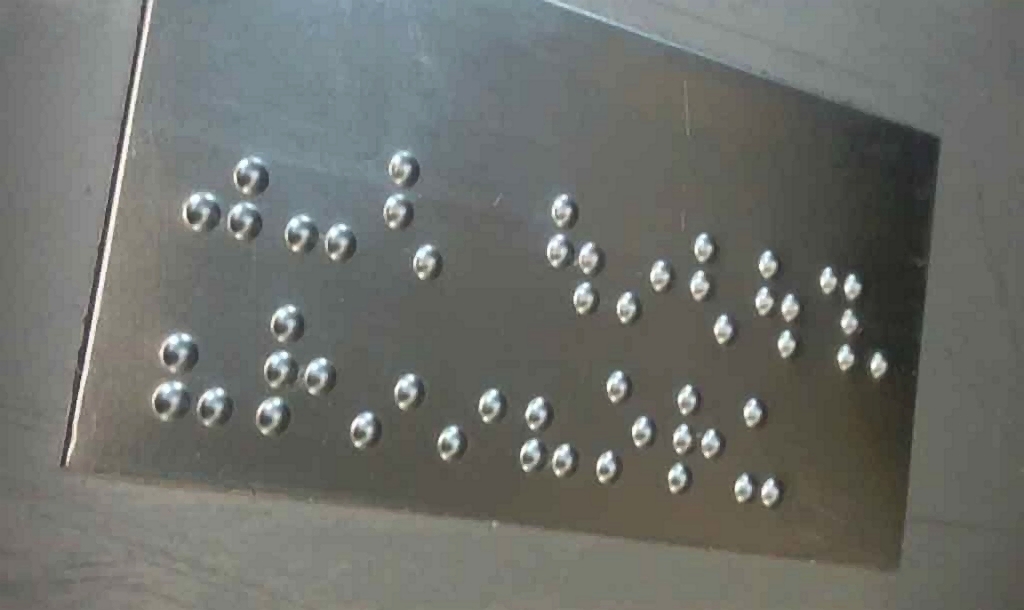

Chances are that if you use a lift in Singapore, you’re already somewhat familiar with Braille signs … as they are found on every lift button in Singapore. This is because BCA’s code on accessibility has long maintained that lift upgrades include accessibility signs for the blind and visually impaired.

But did you know that as of 2014, BCA requires building renovations to include the installation of certain Braille signage to assist individuals with a visual handicap navigate the building? At present, handrail Braille signs that communicate the floor level in each direction and at each end of a staircase are mandatory, and we are sure the list of Mandatory Braille signs will be extended in future to convey other information to users.

As international Braille signs are costly to obtain and don’t necessarily comply fully to BCA’s requirements, we aimed to become a market leader in Braille signage by extending our production technologies to include tactile accessibility sign production.

So that explains the ‘why’ part about Maneki Signage’s move to provide superior Braille signs to the Singapore market. But another equally important question is the ‘how’ part. After all, Braille signs are hardly a new invention, and there have been many innovations in how Braille signage is manufactured globally. Let’s cover the three most popular Braille signage manufacturing methods used today:

Braille reverse-engrave / insert method

- Machining passes required: 3

- Durability: 2.5/3

- Tactility: 3/3

- Variety (material/color/graphics): 2/3

Traditionally, Braille signs started out as one of various substrates into which holes are drilled into whatever Braille pattern is desired. Braille pellets or small ball bearings are then punched into the holes to give the desired raised dot effect.

This method is very durable and can be provided in various materials and colors, thanks to spectrum of colors Braille pellets are available in. Provided a precision Computer Numeric Controlled machine is used (as we use at Maneki Signage), and the correct drill bits and quality stainless steel ball bearings are used, the durability can rival that of the Braille stamp method in everyday use.

The Braille insert method, though, does have a slower and costlier production process as compared to the next two methods, but we insist on this manufacturing process to ensure durability (and we back it up with a 1-year guarantee against material failure).

Finally, this method does allow for raised graphics (as required by the ADA and BCA). These are separately machined from PVC sheets and permanently adhered to the sign surface, creating smooth, raised pictogram and lettering in a variety of colors. Due to the cheapness, abundance, and durability of the raw materials required for making this type of Braille sign, the cost to produce higher quantities of this type of Braille sign is the lowest of all methods covered in this article, and ensures the second highest overall durability (second only to the ‘stamp’ method).

Braille stamp method

- Machining passes required: 1

- Durability: 3/3

- Tactility: 1/3

- Variety (material/color/graphics): 1/3

The Braille stamp method uses a series of metal stamps that are driven into either a metal or plastic sheet at high force to permanently create an impression on the opposite surface. This method is the same as how the raised numbers are stamped on Credit Cards.

The selection of materials and colors compatible with this method are more limited, as certain materials simply cannot be stamped to form an indent (wood being a perfect example). Also, the base material used must be thin, so as to get the best possible indentation. For this reason, materials thicker by only a few millimeters may produce little or no raised surface once stamped and graphical shapes are much harder to achieve as each graphic requires its own metal stamp—and these are costly tools, so graphics options are limited when using this method.

Furthermore, this method produces reduced tactility when certain materials and material thicknesses are used, due do the way the stamp deforms the material—which forms a radius between the braille peak and the surface of the material. This can reduce tactile feedback for people who are still learning Braille and developing their sensitivity to reading Braille signs out in the real world—where there are a lot more distractions than what someone may be used to when reading Braille at home.

So despite this method offering the highest durability, it simply does not conform to our expectations of what a quality, easy-to-use Braille sign should be. And, as such, we do not offer this option.

And finally, due to the manual process involved in setting up the stamp layout and activating it (usually via a manual hydraulic press), this method tends to be laborious and costly, resulting in longer lead times and reduced savings.

Braille 3D UV printing method (discontinued due to durability issues)

- Machining passes required: 1

- Durability: 1/3

- Tactility: 2/3

- Variety (material/color/graphics): 3/3

Despite this method of producing Braille signs becoming more popular nowadays and offering intricate colors, graphics, and gradients for Braille signs, our own internal testing of the durability of UV-printed Braille signs resulted in us producing a limited production run and then (after 6 month’s of internal testing) abandoning the technology in favor of the reverse-engrave/insert method. 3D UV-printing has too many limitations to make it the de facto method for producing quality Braille signs. Here are some of the major limitations:

1. Expensive and uncommon materials – special types of acrylic and aluminium sheets treated with a special primer to ensure even a moderate level of adhesion of the ink to the surface. The much greater cost of these specialized materials (and no readily-available local supply) means that the price of producing Braille signs in this way is more expensive than the other two methods covered.

2. Fragile in the best of circumstances – UV-cured ink decays rapidly in outdoor conditions and will only carries a 6-month, highly-conditional manufacturer guarantee for indoor conditions only. The UV-printed Braille dots are particularly prone to falling off over time and when subjected to stresses that are inevitable in a real-world scenario (such as someone accidentally brushing up against the sign mounted on a handrail, or children playing with the Braille dots).

3. Meticulous manufacturing process – Despite requiring only 1 machine pass to produce, the UV-printer needs to be operated in near laboratory conditions. Any dust will drastically affect adherence by interfering with the primer or ink; the UV-cured in itself needs to be kept in constant flow to prevent clumping, and even after a successful print, the curing process may not be complete and more time is needed in sterile conditions with the right type of lighting to ensure the ink actually sets hard.

With all the aforementioned limitations of UV-printed Braille discovered in our 6-month long trial run of the technology, we had no choice but to discontinue use of this method in favor of a more cost-effective and durable alternative right for the Singapore market.

In closing

We at Maneki Signage are proud to support the blind and visually impaired community in Singapore as well as the thoughtful legislation by the BCA.

If you need any Braille signs to complete your renovation project, visit our Braille sign catalog for online ordering. If you have any questions about our Braille signage products, or want to see a physical sample, contact us (click the floating button on the right edge of the screen) to arrange a site visit or consultation for all your Braille signage needs.

Local and international standards our Braille signs comply with:

- BCA – code on accessibility 2013 – compliant for accessibility signs (official PDF document)

- ADA-approved Braille signs (official PDF document)